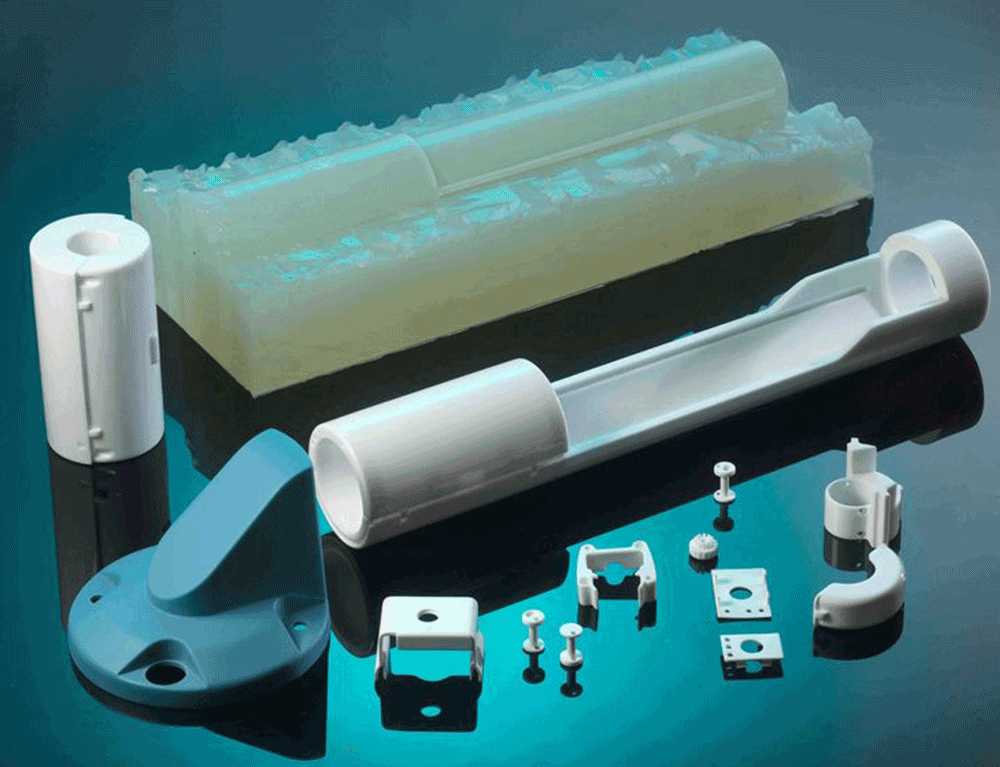

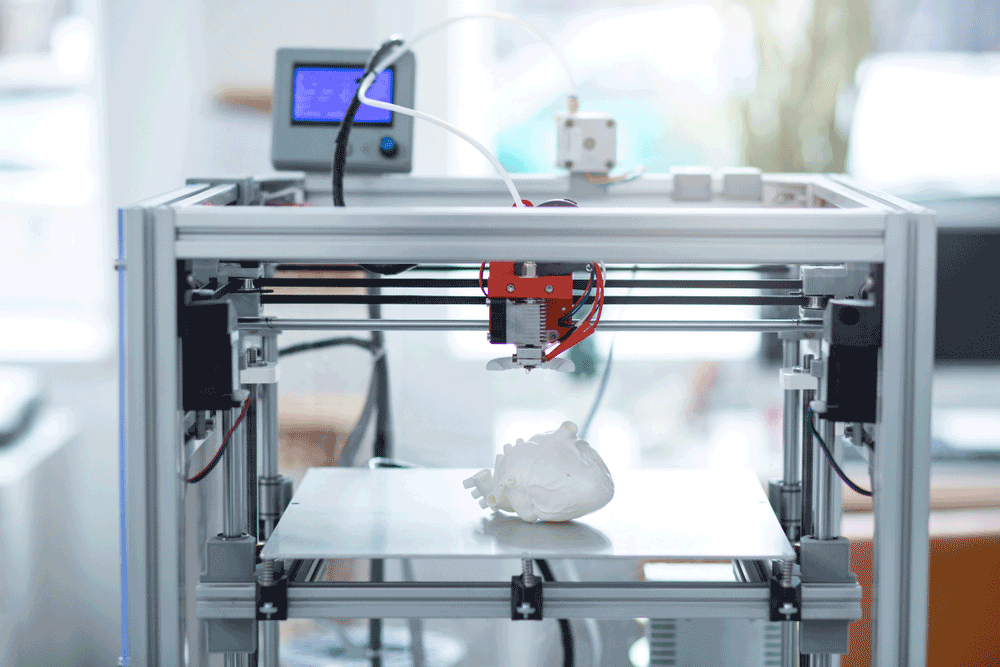

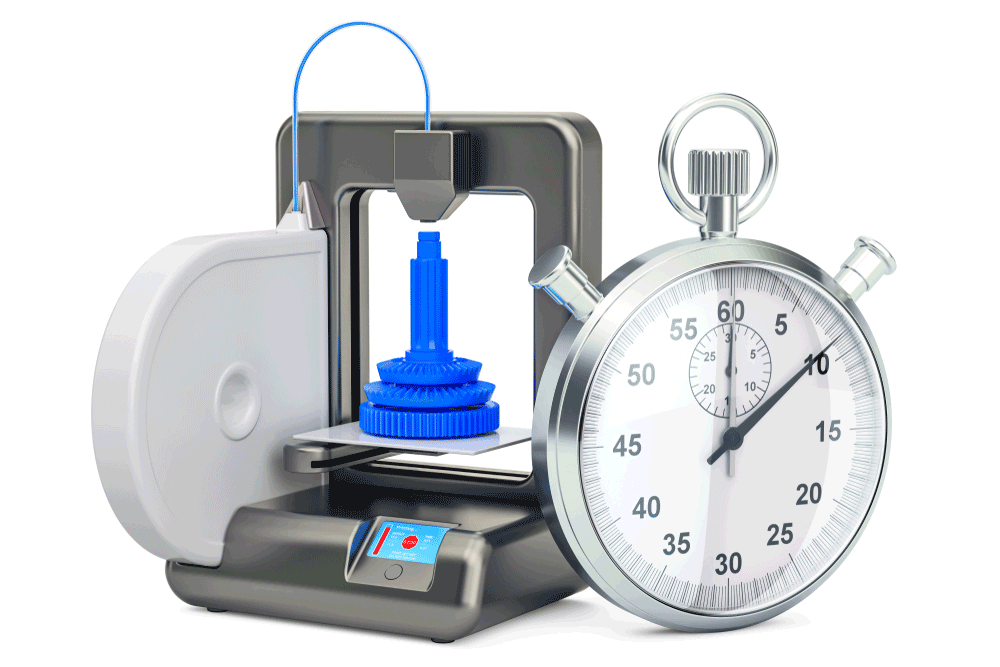

Welcome to Quick Shape's Vacuum Casting Services, where precision meets versatility in the world of rapid prototyping and low-volume production. Vacuum casting is a tried-and-true technique that enables the creation of high-quality, detailed prototypes and end-use parts with exceptional precision and surface finish. Explore the capabilities of vacuum casting with Quick Shape and discover how this technology can take your projects to the next level.

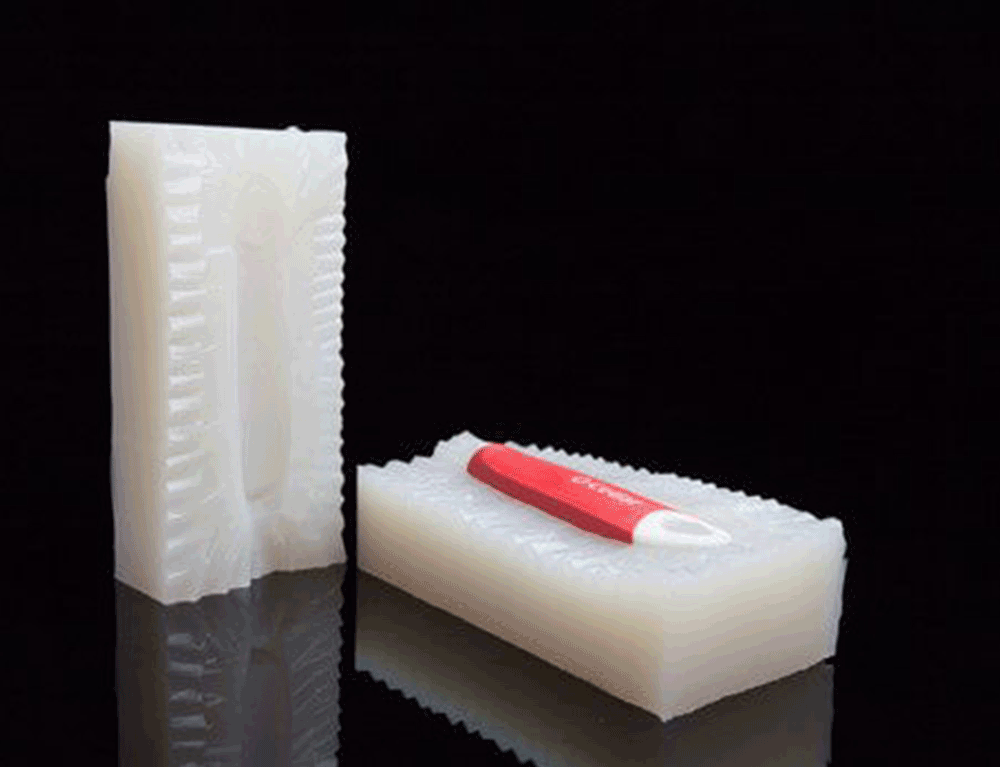

Vacuum casting, also known as urethane casting or polyurethane casting, is a manufacturing process that replicates parts and prototypes using silicone molds and polyurethane resins. It is widely regarded for its ability to produce parts with excellent detail, surface finish, and material properties that closely resemble those of injection-molded components.

Quick Shape's Vacuum Casting Services cater to a diverse array of industries, including:

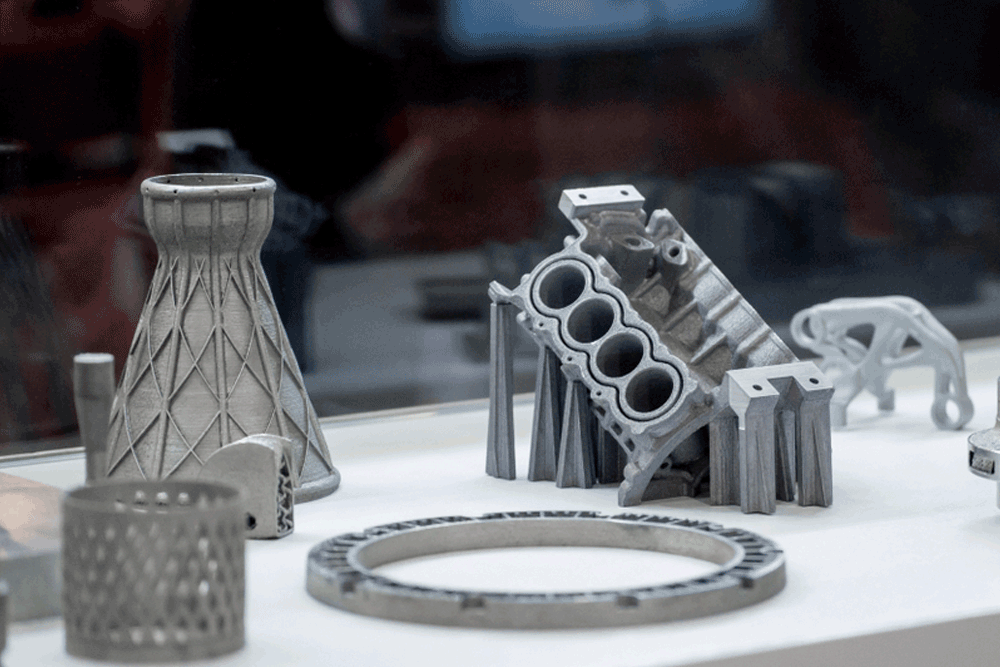

The applications of vacuum casting are wide-ranging and include:

Develop prototypes that closely simulate the final product's appearance and functionality.

Produce low-volume end-use components with the strength and precision required for real-world applications.

Craft personalized products and components tailored to specific requirements.

Facilitate low-volume production runs efficiently and cost-effectively.

Ready to experience the precision and versatility of vacuum casting? Contact Quick Shape to discuss your project, request a quote, or learn more about how vacuum casting can elevate your designs and production processes. Our team of experts is here to guide you through the process and help you achieve outstanding results with the accuracy of vacuum casting. Elevate your projects with Vacuum Casting services from Quick Shape. Let's bring your ideas to life, one detailed cast at a time.