Welcome to Quick Shape's Injection Molding Services, where precision meets efficiency in the world of high-quality plastic and metal part production. Injection molding is a proven manufacturing process that allows for the rapid, cost-effective production of complex and durable components. Explore the capabilities of injection molding with Quick Shape and discover how this technology can transform your projects

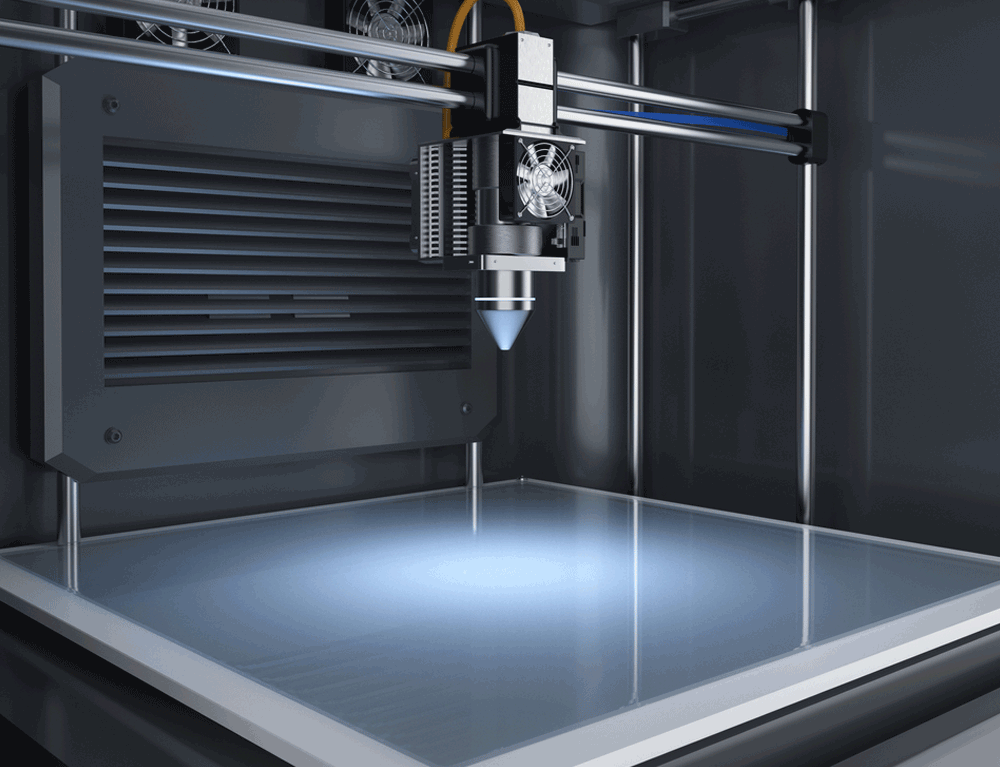

Injection molding is a manufacturing process that involves melting a plastic or metal material and injecting it into a mold cavity under high pressure. Once the material cools and solidifies, the mold is opened, and the finished part is ejected. Injection molding is known for its ability to produce large quantities of parts with consistent quality and tight tolerances.

Quick Shape's Injection Molding Services cater to a wide range of industries, including:

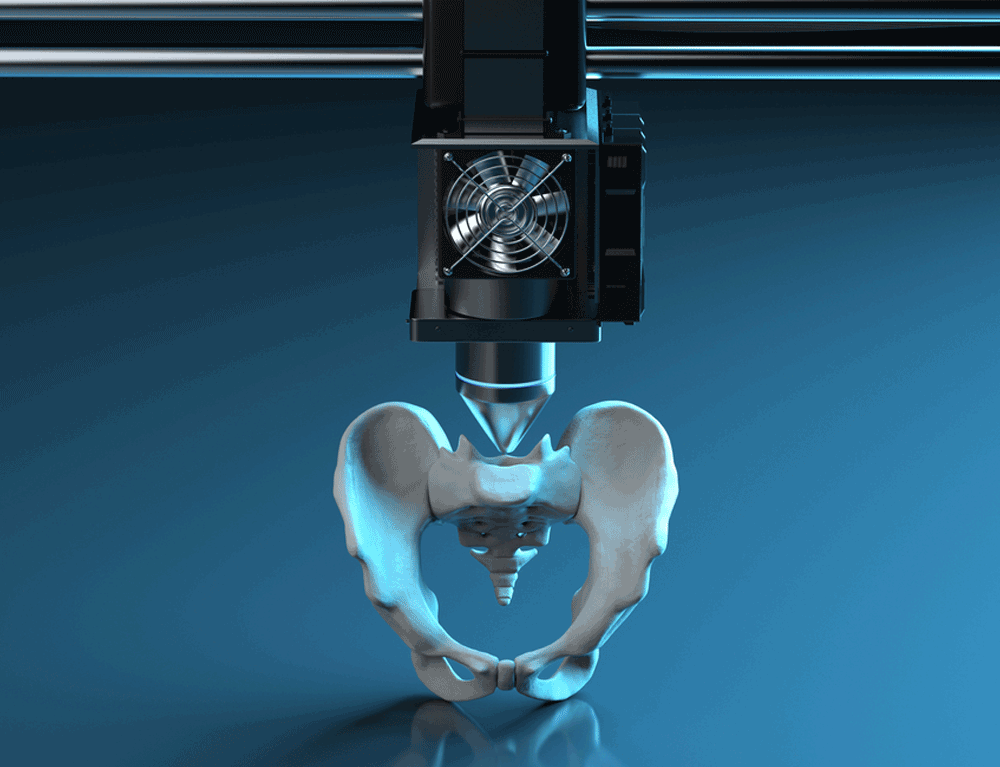

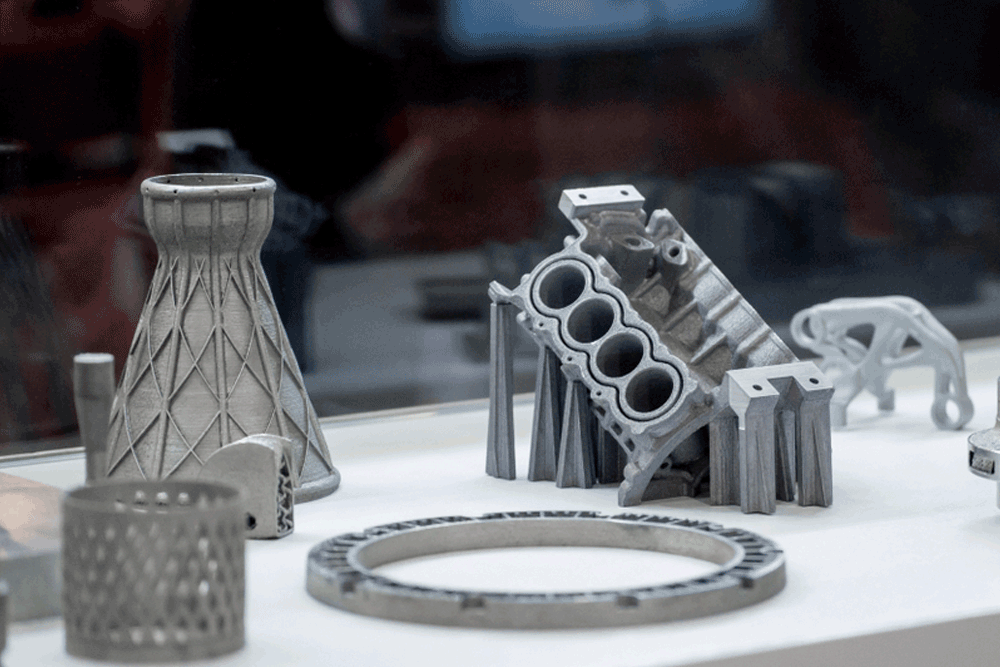

The applications of injection molding are diverse and include:

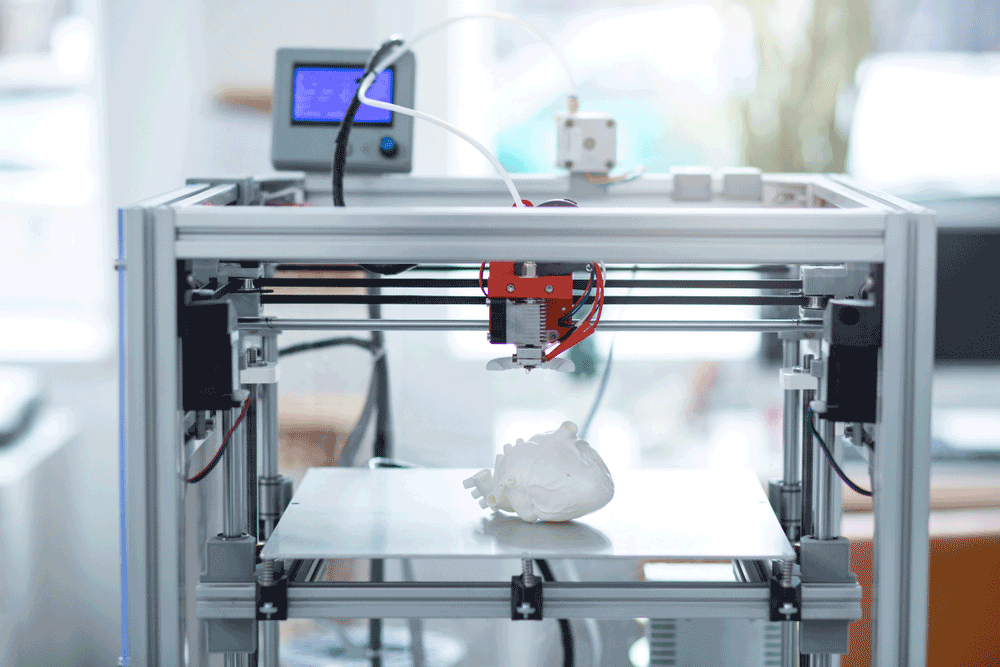

Develop prototypes that closely match the final product for testing and validation.

high-quality, durable components suitable for real-world applications.

Craft customized parts tailored to your exact specifications.

Efficiently manufacture large quantities of parts with consistent quality.

Ready to experience the precision and efficiency of injection molding? Contact Quick Shape to discuss your project, request a quote, or learn more about how injection molding can streamline your production processes. Our team of experts is here to guide you through the process and help you achieve outstanding results with the precision of injection molding. Elevate your projects with Injection Molding services from Quick Shape. Let's bring your ideas to life, one precisely molded part at a time.